R&D, Research and Development

![]()

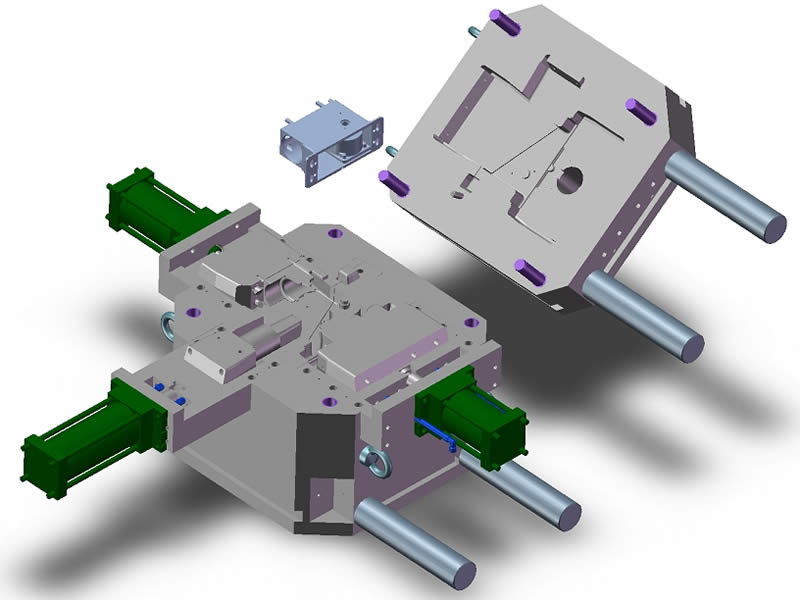

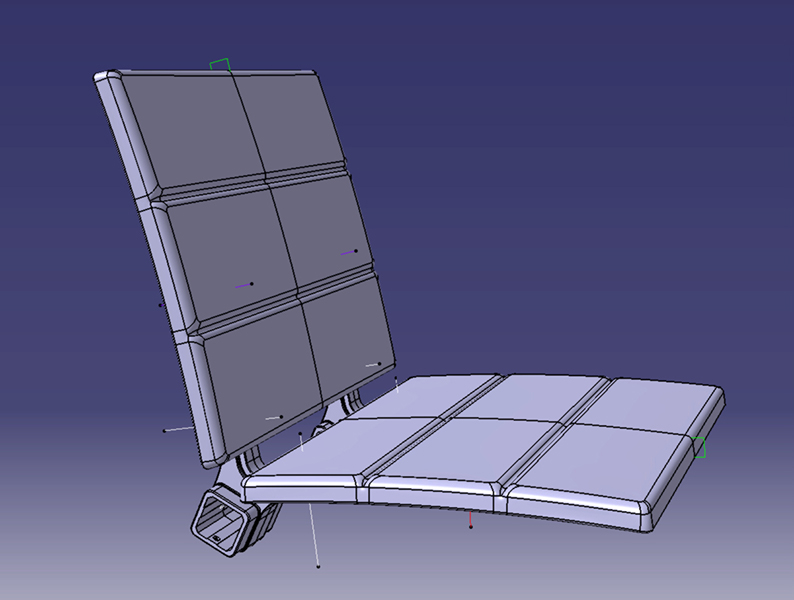

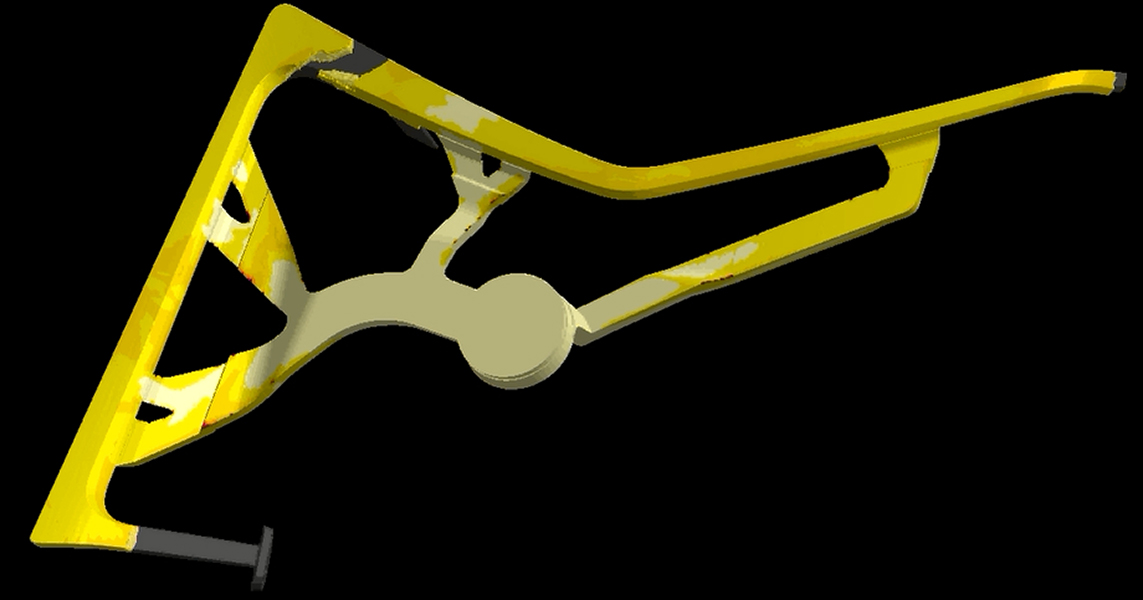

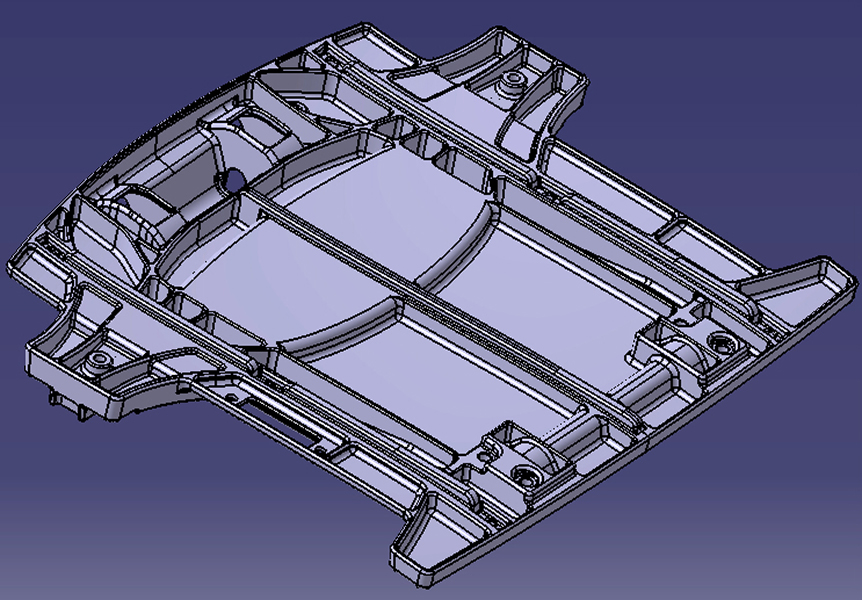

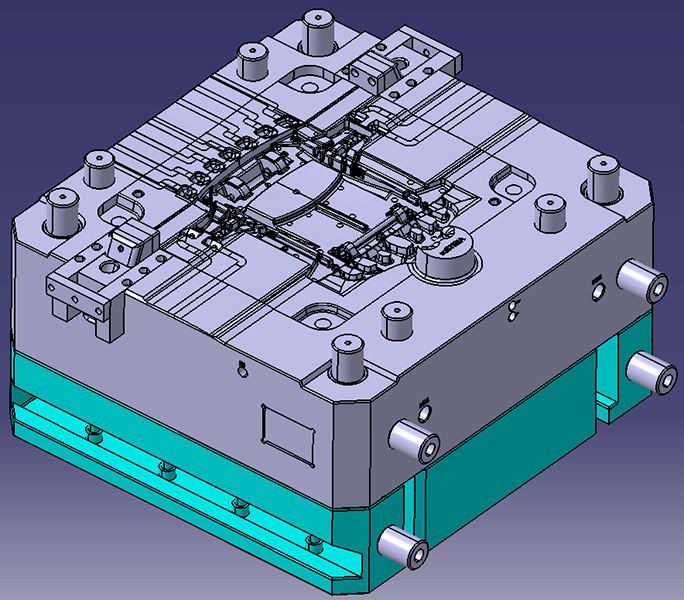

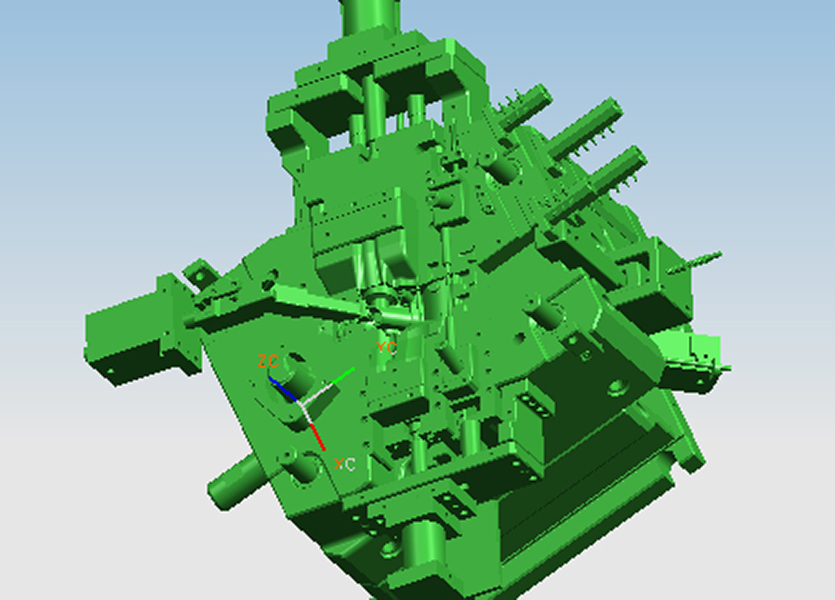

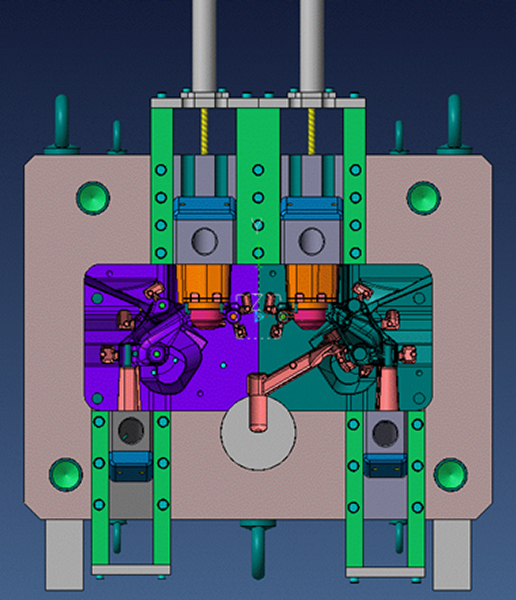

Our Technical Department is provided with the most modern software and Technological equipment. We can design moulds for aluminum die casting production of any requested shapes, dimensions and level of complexity, by using squeeze pins, vacuum and soft casting.

The design processing can be realized according to Customer’s drawing or co-design, with the aim of improving technical and aesthetic performances of the product, through our Know How and our Professional Team.

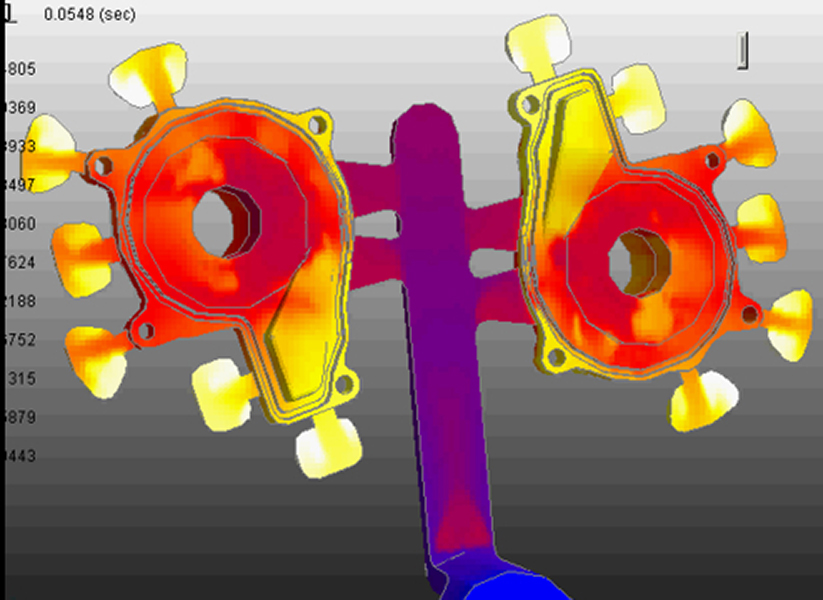

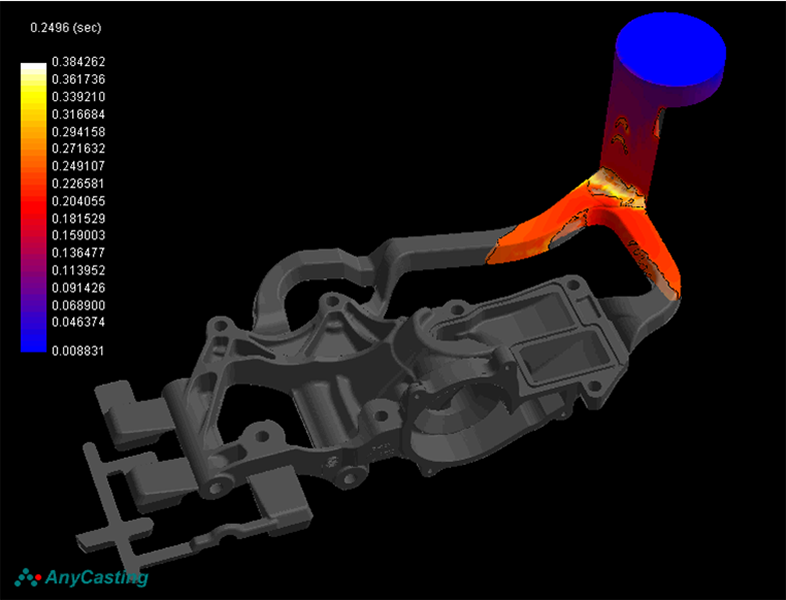

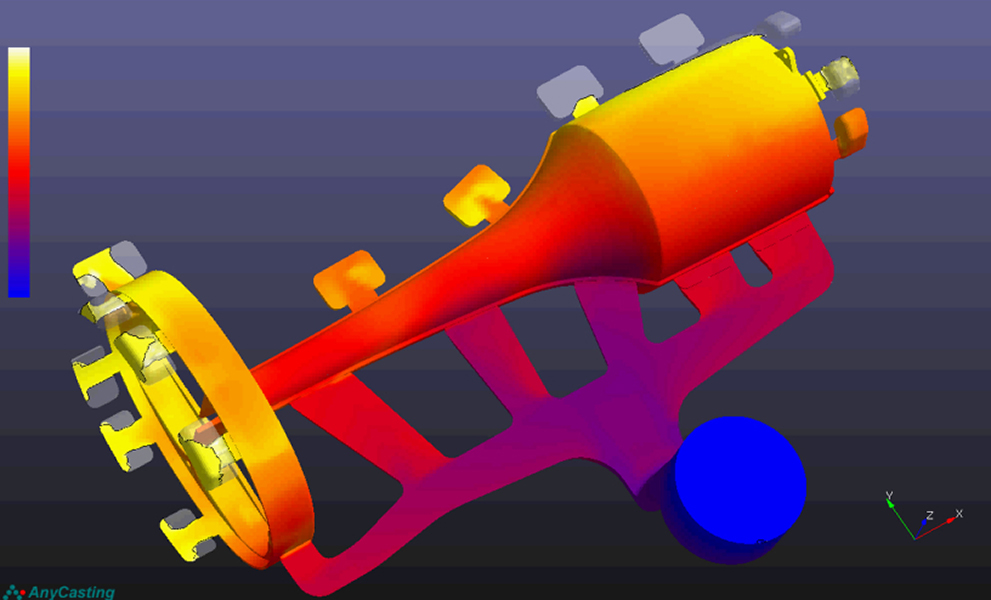

Our customers, during the product industrializing phase, are assisted by our high qualified staff , by providing with process simulations in order to:

- Obtain the best filling of the mould with the least steel stress;

- Detect potential porosities, shrink cavities and cold areas etc.;

- Define the thermoregulation circuits of the mould;

- Optimize the design during the industrializing phase;

- Reduce the test times and set up of moulds.

To do this, our Technical Department makes use of following tools and programs:

- CAD Software, for the design, particularly:

- CATIA: for the 3D modeling, the product industrialization, 3D and 2D design;

- UG: for 3D modeling, product industrialization, 3D and 2D design;

- AUTOCAD: for 2D design;

- SOLIDWORKS: for 3D design.

- MAGMA, PROCAST, ANYCAST, QUIKCAST, CASTLE and FLOW-3D software to obtain the filling simulation and the die casted products solidification.

Our intention is to provide ourselves with additional software and equipment for the Quality Control, in order to best satisfy our Customers.

We are also members of AQM (Material Quality Association) Technical Service Center for Industries, making special mechanical and metallurgic tests.